Shearing Machines

Our Shearing Machines are essential in metal fabrication, offering precise and efficient cutting of various metal sheets and plates. With sharp blades and customizable configurations, they handle materials like steel, aluminum, and stainless steel with accuracy. These machines operate at high speeds, ensuring productivity without compromising cut quality. Some models allow adjustable cutting angles for beveled cuts and complex shapes. User-friendly controls and safety features prioritize ease of operation and a secure working environment. Built durably and backed by comprehensive support services, our Shearing Machines deliver reliable performance, minimal downtime, and enhanced productivity for industries such as manufacturing, construction, and automotive, meeting the diverse cutting needs of modern metalworking processes.

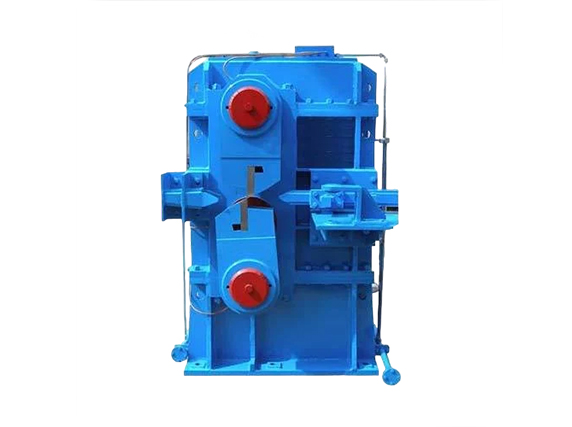

Flying Shears

- Line speed: Up to 30 MPM

- Cutting capacity: 8mm to 32mm

- Built-in Lubrication

- Hardened and ground gear, Silent in Meshing

- Flying shears find application in different applications from cutting material on fly to filling bottles being fed on conveyor and others

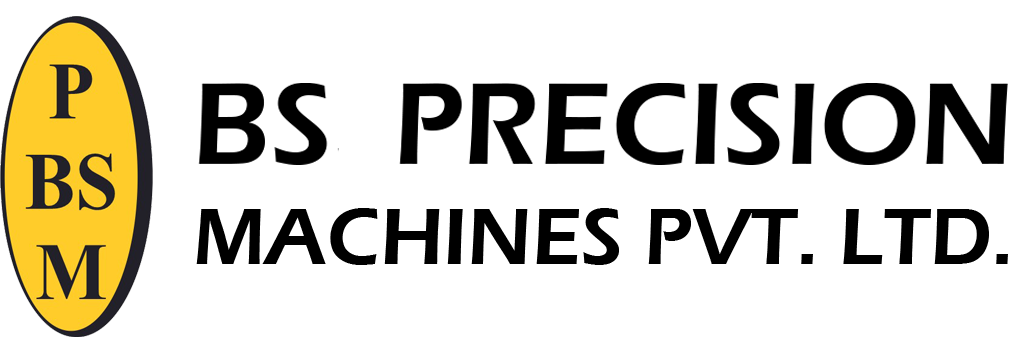

Crop Com Cobble Shears

- Precision designed and finished steel fabricated construction

- Double bored finish with support of pulley-cum-fly wheels and alloy steel pinions

- All shafts made from superior grade steel so as to provide for durable performance

- Centralized oil lubrication system to deliver optimum performance values in the machines

- System helps in achieving close cut lengths

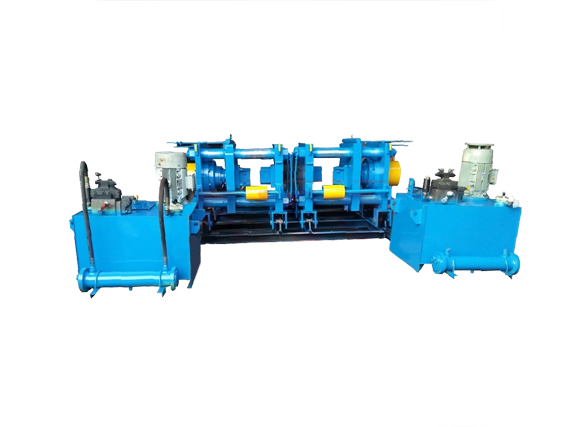

Billet Shearing Machine

- Machines are made to cut different sizes of billets, blooms, and slabs

- Prime MS Plate for body fabrications

- Easily installed in rolling mill

- Excellent production capacity

- Sturdy in construction

- Manufactured out of forged steel

- Heavy Duty Spherical Roller Bearings

- A weight control system of cut blanks

Hot Billet Shearing Machine

- Mechanical Both Type

- Best quality and precise design

- Compact & sturdy design

- Suitable for Single Line as well as double line furnance

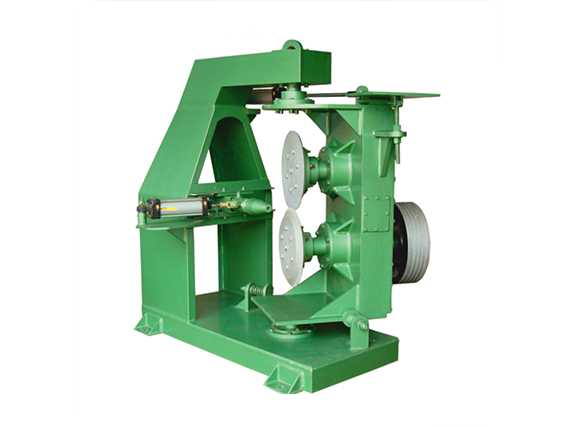

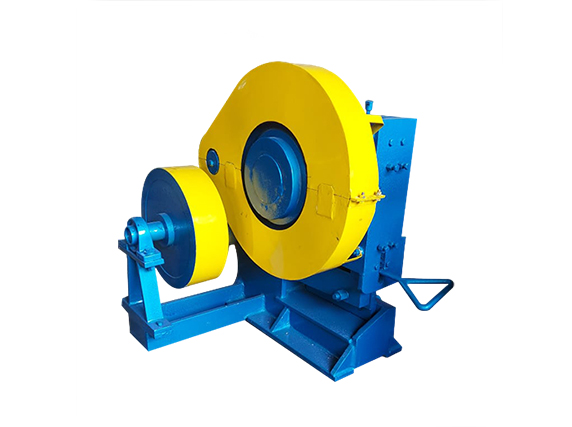

Rotary Shearing Machine

One of the vital benefits of Revolving Shearing Machines is their capacity to perform persistent cutting and shearing activities. The turning sharp edges move quickly through the material, guaranteeing a smooth and consistent cutting interaction. This component fundamentally improves efficiency and lessens handling time, going with it an optimal decision for high-volume creation conditions.

- Used in form of pairs between roughing as well as intermediate finishing stands for cropping front & back ends in TMT Bars/Wire Rods

- Continuous rotating sheer that assists in cutting even larger sheets

- Shears specifically designed for trimming of hot rolled bars at lower speeds

- Shearing blades of superior grade steel

- Sturdy in construction

End Cutting Shearing Machine

End Cutting Shearing Machines come furnished with state of the art innovation, frequently integrating PC mathematical control (CNC) frameworks to accomplish prevalent precision and repeatability. CNC-driven machines take into consideration mechanized cutting cycles, decreasing the gamble of human mistake and advancing efficiency. Administrators can program the ideal aspects and shapes, and the machine executes the cuts definitively, guaranteeing consistency across various workpieces.

- Cutting Capacity: 6 mm to 75 mm

- Available upto 8" billet cutting, Slab cutting capacity 14" & 4"

- PH. Bronze bushing on Crank Shaft 4/8 Gears.

- 4/8 Gears, Clutch / Non clutch type, Strokes per minute 6-30

- Heavy duty spherical roller bearings, Steel fabricated rigid body

- Manufactured out of forged steel

Cold Shearing Machine

- Expertise in manufacturing shearing machines for all types of bars, rounds as well as other structural products

- Double bored construction with Pulley-cum-Fly Wheels and Alloy Steel Pinion support

- Steel fabricated sturdy cased body.

- Fully hardened EN19 gear.

- Tempered carbon steel cutters

- C.I. casted flywheel.

- Anti friction bearing and gun metal bush

- Fully Machine EN8 Shafts.

Snap Shearing Machine

Offered scope of Snap Shear Machine is made by our able experts utilizing extraordinary quality natural substance that is Obtained from the most trusted and reliable sellers of the business. One can benefit this scope of item from us all things considered sensible costs.

Scrap / Plate Shearing Machine

Our Plate/Scrap Shearing Machines is made by our specialists utilizing the best quality part that is gained from industry permitted merchants of market. This item is utilized in various spots. We present our items at low costs.

- Steel Fabricated & Machined construction

- Double bored with Pulley-cum- Fly Wheels Alloy Steel Pinions.

- All shafts made from EN-8 Steel.

- Centralized oil lubrication system.

- Complete in all respect.

- The tailor-made suit as per customer requirement

- Low power consumption

- Manual and Automatic operation

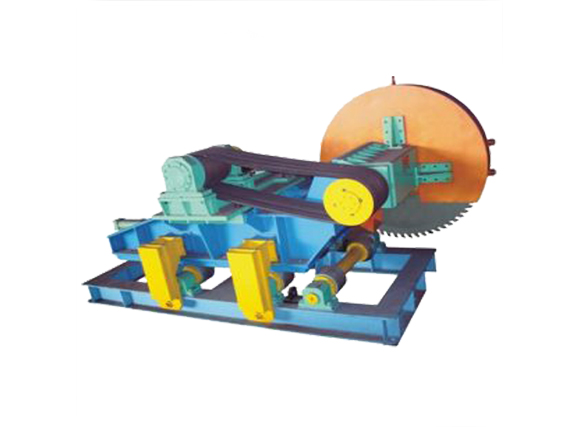

Hot Saw

The Hot saw Sharp edge of the Fixed and voyaging Saw, plunges at right point to the moving hub cutting the part at the front end as well as at the necessary lengths by Voyaging hot saw In the wake of cutting the hold is delivered and the cut area is followed through on the cooling bed.

- Comes with tough strong teeth

- The Hot Saw presently is of two types Pendulum Swinging type and the other is of horizontal shift type.

- Corrosion Resistance

- Highly durable

- Made from quality stainless steel